Superior reliability: SAMOA PIVOT Series Air Motor technology for diaphragm pumps

Enhanced operational reliability with PIVOT Series Air Motor technology

Air-operated diaphragm pumps play a crucial role in many industrial processes thanks to their versatility and reliable operation. The design lacks an electric motor, gearbox and rotating shaft seals, making them a sustainable choice for demanding environments. Instead, compressed air is used to drive two diaphragms, which in turn create an efficient fluid flow.

Choosing the right pump requires a close look at the air motor technology. The design affects everything from operational reliability and maintenance requirements to energy efficiency. A well-built air motor can make a big difference by eliminating common problems such as downtime, unnecessary wear and tear and inconsistent performance at low air pressure.

Reliability – avoid unplanned stops and expensive repairs

When pumps are used in harsh environments, it is crucial that the air motor is built to last. Designs with sliding spools, O-rings or other wearing parts often require service and can lead to unplanned downtime. Every interruption in production means both time and money lost.

Another important aspect is the ability of the air distribution to keep the pump running without getting stuck. Many models on the market are sensitive to stops and require additional components, such as springs or latching mechanisms, to restart in the event of a failure. Since these parts wear out quickly, especially with unconditioned compressed air, this can result in recurring problems and increased maintenance costs.

Another important aspect is the ability of the air distribution to keep the pump running without getting stuck. Many models on the market are sensitive to stops and require additional components, such as springs or latching mechanisms, to restart in the event of a failure. Since these parts wear out quickly, especially with unconditioned compressed air, this can result in recurring problems and increased maintenance costs.

Smoother operation with proper air distribution

To avoid uneven flow and excessive vibrations, it is important that the air motor operates smoothly, even at low air pressure. Pulsations and strong movements can cause wear on pipelines and valves, which leads to both poorer performance and increased maintenance requirements.

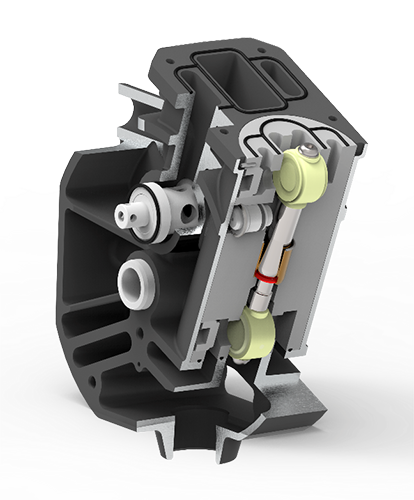

SAMOA Industrial's PIVOT series pumps feature a patented air distribution technology based on a frictionless swing valve. The unique feature of this solution is that only a single moving part is used – a swinging rod with sealing pads at each end.

The well-thought-out design provides a reliable and long-lasting pump, unlike traditional models with multiple sliding spools that wear down over time.

For extra stability and safe operation at low air pressure, the pumps are also equipped with Smooth Start Shifter (3S). This technology ensures that the air distribution is activated at exactly the right time, which means soft start and smooth operation without sudden interruptions.

Avoid ice formation and power Loss

Ice formation in the air motor is a common challenge, especially during continuous operation. As the exhaust air expands, it cools down, which can cause moisture in the compressed air to freeze and block the air passages. This affects performance and, in the worst case, can stop the pump completely.

To combat this problem, the PIVOT series air motor has extra-large outlet passages that prevent ice formation. By ensuring a smooth, unrestricted airflow, the pump can operate stably even at low temperatures and during prolonged use.

To combat this problem, the PIVOT series air motor has extra-large outlet passages that prevent ice formation. By ensuring a smooth, unrestricted airflow, the pump can operate stably even at low temperatures and during prolonged use.

Easier maintenance and longer life

The ease of servicing and maintaining a pump affects both costs and uptime. A modular design can make a big difference by simplifying the replacement of wear parts and minimizing downtime.

The air valve cartridge in the PIVOT series pumps is designed to be easily accessible and can be replaced in minutes. Keeping the number of moving parts to a minimum also reduces the risk of wear and operational problems.

The air valve cartridge in the PIVOT series pumps is designed to be easily accessible and can be replaced in minutes. Keeping the number of moving parts to a minimum also reduces the risk of wear and operational problems.

Summary – what to look for in an air-driven diaphragm pump?

To get a pump with high performance and long service life, air motor technology is crucial.

Some important factors to consider are:

• Design without wear-prone sliding spools and O-rings

• An air motor that prevents unexpected stops and keeps production going

• Smooth operation with minimal vibrations and liquid pulsations

• Technical solution that prevents ice formation and power loss

• Easy service and a maintenance-friendly system

The PIVOT series from SAMOA Industrial offers an air distribution technology that meets these requirements. With a patented swing valve, Smooth Start Shifter (3S) and a design that prevents ice formation, you get a stable and reliable pump that works even under the most demanding conditions.

Some important factors to consider are:

• Design without wear-prone sliding spools and O-rings

• An air motor that prevents unexpected stops and keeps production going

• Smooth operation with minimal vibrations and liquid pulsations

• Technical solution that prevents ice formation and power loss

• Easy service and a maintenance-friendly system

The PIVOT series from SAMOA Industrial offers an air distribution technology that meets these requirements. With a patented swing valve, Smooth Start Shifter (3S) and a design that prevents ice formation, you get a stable and reliable pump that works even under the most demanding conditions.

Want to know more?

Fill in your details below, send a message or contact Svante Fogelhamre directly:

Mail: svante.fogelhamre@altenec.se

Mobile: +46 76 163 01 79