Customer Case: Streamlining Cleaning Processes with SAMOA Industrial's Pivot UP10 1" Diaphragm Pumps

Background

A leading manufacturer of aluminum parts for the automotive industry sought to optimize its cleaning processes. The primary objective was to effectively wash away chips and cutting fluid from machined parts. The company faced significant issues with its existing pump systems, including corrosion and frequent maintenance, due to exposure to aggressive detergents.

Challenges

The cleaning process involved highly concentrated and corrosive chemicals, which posed the following challenges for the previously installed pump systems:

Corrosion Susceptibility:

The aggressive detergents caused rapid wear and tear on pump components.

Frequent Downtime: The pumps required constant maintenance, disrupting production schedules.

Spare Part Availability: Difficulty in sourcing replacement parts led to extended downtimes.

Increased Maintenance Costs: Frequent repairs and part replacements drove up operational costs.

Reduced Production Efficiency: Downtime and inconsistent performance negatively impacted overall productivity.

The Solution

To address these issues, APG Tools recommended the installation of SAMOA Industrial's UP10 diaphragm pumps, customized for various stages of the cleaning process. Key adaptations included:

Material Compatibility:

The pumps were equipped with chemically resistant materials to withstand aggressive detergents and corrosive cleaning agents.

High Performance: With their robust construction, UP10 pumps ensured reliable operation even in demanding environments.

Low Maintenance Requirements: Designed to minimize wear and tear, the pumps reduced the frequency of repairs, leading to greater uptime.

Ease of Integration: The compact and versatile design allowed seamless integration into the customer’s existing cleaning systems.

A leading manufacturer of aluminum parts for the automotive industry sought to optimize its cleaning processes. The primary objective was to effectively wash away chips and cutting fluid from machined parts. The company faced significant issues with its existing pump systems, including corrosion and frequent maintenance, due to exposure to aggressive detergents.

Challenges

The cleaning process involved highly concentrated and corrosive chemicals, which posed the following challenges for the previously installed pump systems:

Corrosion Susceptibility:

The aggressive detergents caused rapid wear and tear on pump components.

Frequent Downtime: The pumps required constant maintenance, disrupting production schedules.

Spare Part Availability: Difficulty in sourcing replacement parts led to extended downtimes.

Increased Maintenance Costs: Frequent repairs and part replacements drove up operational costs.

Reduced Production Efficiency: Downtime and inconsistent performance negatively impacted overall productivity.

The Solution

To address these issues, APG Tools recommended the installation of SAMOA Industrial's UP10 diaphragm pumps, customized for various stages of the cleaning process. Key adaptations included:

Material Compatibility:

The pumps were equipped with chemically resistant materials to withstand aggressive detergents and corrosive cleaning agents.

High Performance: With their robust construction, UP10 pumps ensured reliable operation even in demanding environments.

Low Maintenance Requirements: Designed to minimize wear and tear, the pumps reduced the frequency of repairs, leading to greater uptime.

Ease of Integration: The compact and versatile design allowed seamless integration into the customer’s existing cleaning systems.

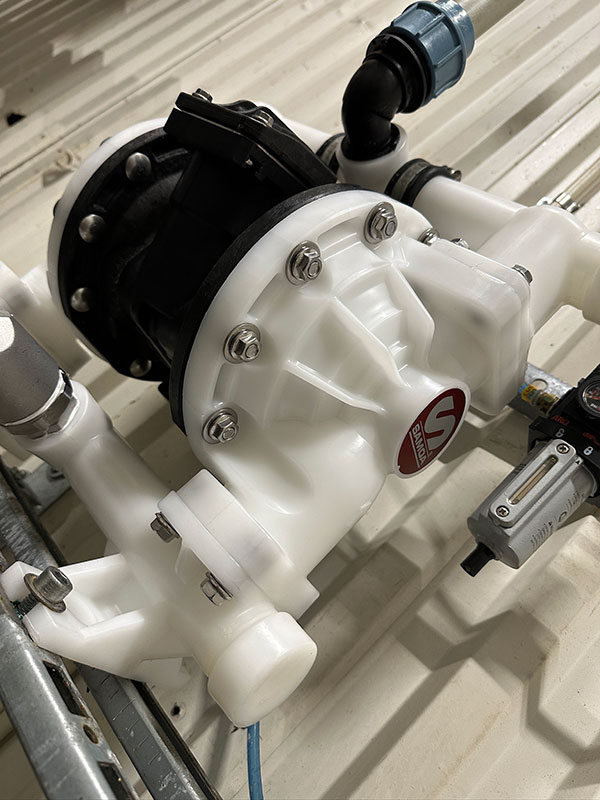

Diaphragm Pump UP10 in plastic with PTFE Membrane

Diaphragm Pump UP10 in plastic with PTFE MembraneThe UP10 Plastic Diaphragm Pump with PTFE Membrane is a versatile and highly durable solution for transferring concentrated detergents from chemical storage to washing stations. Specifically engineered for harsh chemical environments, this pump delivers unmatched corrosion resistance and long-lasting performance, ensuring reliable operation in demanding industrial and commercial applications.

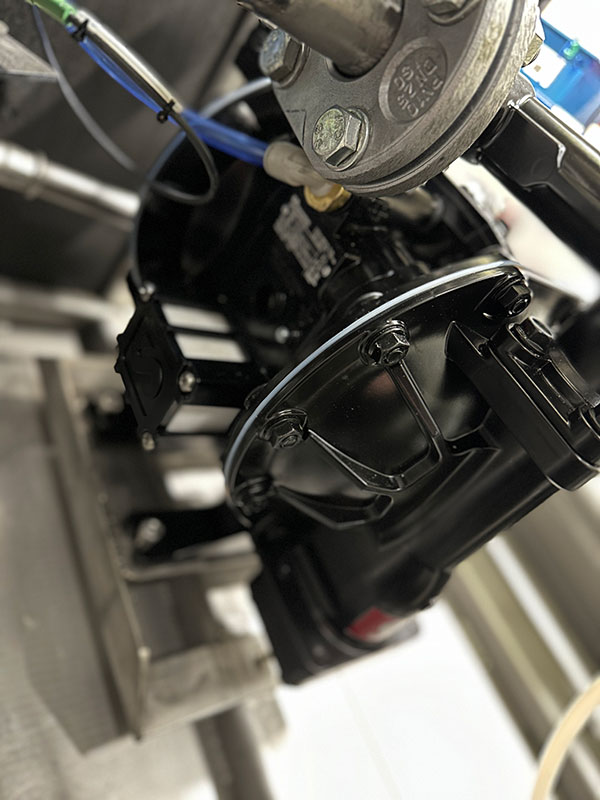

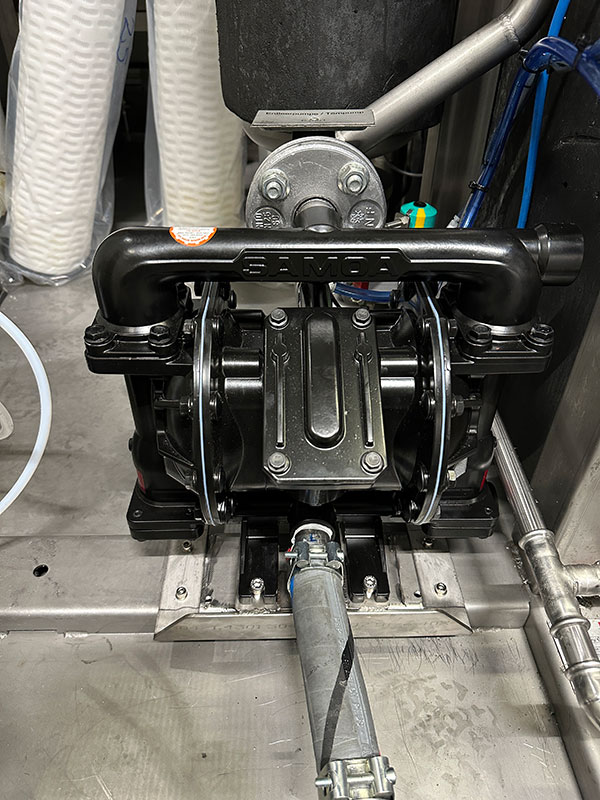

Diaphragm Pump UP10 Aluminum

Diaphragm Pump UP10 AluminumThe UP10 Aluminum Diaphragm Pump is engineered for demanding applications, specifically for handling dirty and abrasive liquids, such as wastewater from washing machines. This robust pump offers a reliable solution for industries requiring consistent and efficient performance when changing or managing water in challenging environments.

Results

By implementing the UP10 diaphragm pumps, the manufacturer achieved the following benefits:

Enhanced Reliability:

The pumps operated consistently, reducing unplanned downtime.

Cost Savings:

Lower maintenance and spare part costs translated into significant operational savings.

Improved Efficiency:

• A streamlined cleaning process resulted in increased production throughput.

• Longer Lifespan -the corrosion-resistant design extended the lifecycle of the pumps, providing a higher return on investment.

Conclusion

The SAMOA Industrial UP10 diaphragm pumps proved to be an effective solution for the challenges faced in the aluminum parts cleaning process. Their durability, reliability, and compatibility with corrosive environments helped the manufacturer optimize operations, reduce costs, and enhance productivity.

For more information on SAMOA Industrial's range of diaphragm pumps, contact us.

Do you have questions?

Contact Svante Fogelhamre

+46 761 63 01 79

Contact Svante Fogelhamre

+46 761 63 01 79